Welcome to our comprehensive guide on residential grinder pump system questions! If you’re a homeowner in Chattanooga, TN, or anywhere else for that matter, and find wastewater management to be a messy business, a grinder pump could be the solution you’ve been looking for.

As a septic-specialist plumber with over 25 years of experience, I understand the importance of having reliable plumbing systems that efficiently handle the disposal of waste.

In this article, we’ll cover an in-depth Q&A for Residential Grinder Pump System Questions!

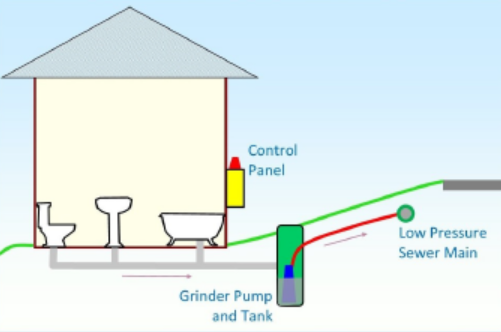

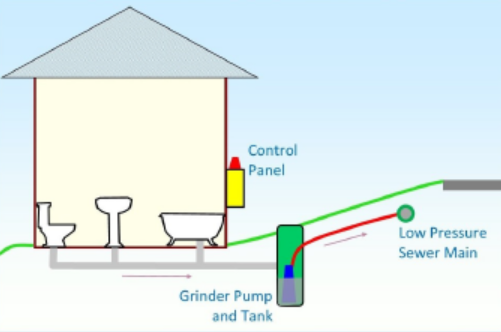

What is a residential grinder pump system?

A residential grinder pump system is a special kind of plumbing system that helps move wastewater from your home to the sewer or septic tank. It uses a powerful motor to grind solid waste into smaller pieces, like a blender, so it can easily flow through pipes.

This system is used when the plumbing in your house is lower than the sewer or septic tank, or when the distance is too long for gravity alone to move the waste.

The grinder pump, usually placed outside your home, has a motor that crushes and pumps the waste through smaller pipes. Let’s m

How does a grinder pump work?

A grinder pump works by grinding up solid waste into smaller pieces and then pumping it through pipes. When wastewater from your home enters the grinder pump, it flows into a holding tank. Inside the tank, there are sharp blades that chop up the waste into smaller bits. Once the waste is ground up, a motor in the pump activates and pumps the wastewater through smaller pipes using pressure.

The grinder pump’s motor has a grinder wheel or impeller, which spins rapidly to grind and break down the waste. This allows the waste to be easily transported through the pipes, even if the plumbing is located lower than the sewer or septic tank, or if the distance is too long for gravity to do the job.

It’s important to note that grinder pumps require electricity to operate. So, if there is a power outage, the pump may stop working. Regular maintenance is also crucial to keep the grinder pump functioning

What are the components of a Residential grinder pump system?

A residential grinder pump system consists of several key components:

- Grinder Pump: The grinder pump itself is the main component. It contains a motor and sharp blades or impellers that grind up solid waste.

- Holding Tank: Wastewater from your home enters a holding tank where it is temporarily stored before being pumped out.

- Control Panel: The control panel is generally located inside your home and controls the operation of the grinder pump. It usually has buttons or switches to turn the pump on or off.

- Alarm System: An alarm system is sometimes installed to alert you if there are any issues with the grinder pump, such as high water levels or pump failure. This allows you to take action and prevent any potential problems.

- Discharge Pipe: The discharge pipe carries the ground-up wastewater from the grinder pump to the sewer or septic tank. It is typically a smaller diameter pipe.

- Vent Pipe: A vent pipe allows air to enter the system, preventing suction and ensuring proper operation of the pump.

- Electrical Connection: The grinder pump requires an electrical connection to power the motor. It is important to ensure proper electrical wiring and connection for safe and reliable operation.

What is a pressure sewer system?

A pressure sewer system is a type of wastewater transportation system that uses pressure to move sewage from homes and buildings to a central collection point or treatment facility. Instead of relying solely on gravity, a pressure sewer system uses pumps to propel the wastewater through small diameter pipes.

Here’s how it works: Each home or building in the system has a grinder pump, which is a device that grinds up the solid waste and pumps it into the system. The grinder pump is usually placed underground, near the building. When wastewater is produced, it flows into the grinder pump, where it is ground up and then pumped through the pressure sewer pipes. These pipes are typically buried shallowly, about 1-2 feet underground.

As the wastewater travels through the system, pressure is maintained to ensure proper movement. The pressure is generated by the grinder pumps and controlled by a central control panel.

Pressure sewer systems are commonly used in areas with challenging terrain or where traditional gravity sewer systems are not feasible or cost-effective. They offer an efficient and reliable way to transport wastewater to the treatment facility.

How is a grinder pump installed?

Installing a grinder pump typically involves several steps:

- Assessment: A professional plumber will assess your property to determine the best location for the grinder pump and the necessary plumbing connections.

- Excavation: A small area of your yard will be excavated to create a pit or vault where the pump will be installed. This is usually located below ground level to allow for gravity flow of wastewater.

- Pump Installation: The grinder pump is carefully placed in the pit or vault. It is securely connected to the incoming wastewater pipe from your home and to the discharge pipe that leads to the sewer or septic tank.

- Electrical Connection: The grinder pump requires electrical power to operate. An electrician will connect the pump to a dedicated electrical circuit to ensure safe and reliable operation.

- Control Panel Setup: A control panel, usually installed inside your home, will be set up to monitor and control the grinder pump operation. This panel may include features such as alarm systems for notifications of any issues that arise.

- Testing and Commissioning: The residential grinder pump system is tested to ensure all connections are secure and working properly. The pump is then commissioned, meaning it is put into active operation.

It’s crucial to have a qualified plumber handle the installation of a grinder pump to ensure it is done correctly and in compliance with local plumbing codes. Additionally, regular maintenance and inspections by a professional plumber are necessary to keep the grinder pump running smoothly and prevent any potential issues.

How is a grinder pump installed?

Installing a grinder pump typically involves several steps:

- Assessment: A professional plumber will assess your property to determine the best location for the grinder pump and the necessary plumbing connections.

- Excavation: A small area of your yard will be excavated to create a pit or vault where the pump will be installed. This is usually located below ground level to allow for gravity flow of wastewater.

- Pump Installation: The grinder pump is carefully placed in the pit or vault. It is securely connected to the incoming wastewater pipe from your home and to the discharge pipe that leads to the sewer or septic tank.

- Electrical Connection: The grinder pump requires electrical power to operate. An electrician will connect the pump to a dedicated electrical circuit to ensure safe and reliable operation.

- Control Panel Setup: A control panel, usually installed inside your home, will be set up to monitor and control the grinder pump operation. This panel may include features such as alarm systems for notifications of any issues that arise.

- Testing and Commissioning: The grinder pump system is tested to ensure all connections are secure and working properly. The pump is then commissioned, meaning it is put into active operation.

It’s crucial to have a qualified plumber handle the installation of a grinder pump to ensure it is done correctly and in compliance with local plumbing codes. Additionally, regular maintenance and inspections by a professional plumber are necessary to keep the grinder pump running smoothly and prevent any potential issues.

What are the risks of a DIY installation for a grinder pump installation?

While the idea of saving money by doing a DIY grinder pump installation may seem appealing, there are significant risks involved. Here are some of the risks associated with DIY installations:

- Safety Hazards: Installing a grinder pump involves working with electrical connections, excavating, and handling heavy equipment. Without proper knowledge and experience, you could expose yourself to electrical hazards, injury from excavation, or mishandling of equipment, leading to accidents or even serious injuries.

- Improper Installation: Grinder pumps are complex systems that require precise installation techniques and knowledge of local plumbing codes. A DIY installation might not adhere to these codes, causing issues with functionality, efficiency, or even compliance. This can result in frequent breakdowns, clogs, or sewer backups.

- System Damage: Incorrect installation procedures, such as improper pipe connections or inadequate support for the pump, can lead to system damage. This may result in leaks, pipe fractures, or even complete system failure, requiring costly repairs or replacement.

- Voiding Warranty: Most grinder pumps come with a warranty that requires professional installation. Installing the pump yourself might void the warranty, leaving you responsible for any repairs or replacements.

- Lack of Expertise: Grinder pump installation requires specific knowledge and experience to ensure proper functioning and longevity. Without the expertise of a professional plumber, you may overlook essential details or make mistakes that could impact the performance of the system.

To ensure a safe and effective installation, it is recommended to hire a qualified septic plumber experienced in grinder pump installations. They have the necessary skills, knowledge, and equipment to handle the installation correctly and in accordance with local regulations. It will provide peace of mind knowing that the system is installed safely and will operate efficiently for years to come.

What is the difference between a grinder pump and a sewage pump?

The main difference between a grinder pump and a sewage pump lies in their functionality and the type of waste they handle.

A grinder pump is designed to grind solid waste into smaller particles before pumping it. It is often used in situations where the plumbing is located lower than the sewer or septic tank, or when the distance is too long for gravity alone to move the waste. The grinder pump grinds the solid waste into smaller pieces, making it easier to pump through pipes.

On the other hand, a sewage pump is designed to transport liquid waste, such as wastewater and sewage, from one location to another. It does not have the grinding capability of a grinder pump. Sewage pumps are typically used in residential or commercial settings to move liquid waste from toilets, sinks, showers, or other plumbing fixtures to the appropriate sewer or septic system.

In summary, a grinder pump is suitable for situations where solid waste needs to be ground up before pumping, while a sewage pump is used to move liquid waste. The choice between the two will depend on the specific needs of the plumbing system and the types of waste being handled. It’s recommended to consult with a professional plumber to determine the appropriate pump for your specific requirements.

How often does a grinder pump need to be serviced?

Grinder pumps require regular maintenance to ensure they continue operating efficiently. The frequency of servicing can depend on various factors, such as the manufacturer’s recommendations, local regulations, and the specific conditions of your plumbing system. However, a general guideline is to have a professional plumbing service your grinder pump once every 1-2 years.

During a regular service appointment, the plumber will inspect the pump, check for any signs of wear or damage, clean the pump and its components, test the operation of the pump, and ensure proper functioning of the control panel and alarm system, if applicable. They may also assess the condition of the discharge and vent pipes and address any clogs or blockages.

It’s important not to neglect regular servicing of your grinder pump, as it can lead to issues like clogs, decreased efficiency, or even pump failure. Regular maintenance helps identify and address potential problems before they worsen and cause costly repairs.

If you notice any issues with your grinder pump, such as unusual noises, frequent pump cycling, or wastewater backups, it’s advisable to have it inspected and serviced by a professional plumber immediately, regardless of the scheduled maintenance timeframe.

What can be done to protect a grinder pump?

Taking steps to protect your grinder pump can help ensure its longevity and proper functioning. Here are some actions you can take:

- Be mindful of what goes down the drain: Avoid disposing of items that could damage the pump or clog the system, such as grease, oils, wipes, feminine hygiene products, and excessive amounts of toilet paper. Stick to flushing only human waste and toilet paper.

- Install a garbage disposal properly: If you have a garbage disposal unit, ensure it is installed correctly and operates smoothly. Avoid putting large quantities of food waste down the disposal that could overwhelm the grinder pump.

- Use water efficiently: Excessive water usage can put a strain on the grinder pump. Be mindful of water usage and conserve water where possible. Avoid letting water run unnecessarily or using large amounts of water simultaneously (e.g., running multiple showers, laundry, and dishwasher at the same time).

- Protect the pump from damage: Ensure the area around the grinder pump is clear and free from debris or other objects that could damage or obstruct the pump. Avoid placing heavy objects on top of the pump or its access covers.

- Schedule regular maintenance: Regularly service the grinder pump as recommended by a professional plumber.

What are the common problems with grinder pump systems?

While grinder pump systems are generally reliable, they can encounter some common problems. Here are a few issues to watch out for:

- Clogs: The most common problem with grinder pump systems is clogging. This can occur if inappropriate items are flushed down the drain, such as grease, wipes, or feminine hygiene products. Clogs can obstruct the pump and pipes, leading to backups or pump failure.

- Motor Issues: Grinder pump motors can experience problems due to wear and tear or electrical issues. Motor failures may result in the pump not working efficiently or not turning on at all. Professional troubleshooting and repair are usually needed for motor-related problems.

- Float Switch Problems: The float switch inside the grinder pump controls its operation by detecting the water level. If the float switch is not functioning correctly, it can cause intermittent pump cycling or failure to turn on or off properly. Adjusting or replacing the float switch may be necessary.

- Power Outages: Grinder pumps rely on electricity to operate. During power outages, the pump may stop working, leading to potential backups. Some systems have battery backups or generator options to address this issue.

- Alarm Activations: Grinder pump systems often have alarm systems that alert

- homeowners to issues such as high water levels or pump malfunctions. If the alarm goes off, it usually indicates a problem that requires attention from a professional plumber.

- Pipe Blockages: Blockages can occur within the pipes leading to or from the grinder pump. This can be caused by the buildup of debris, tree roots entering the pipes, or damage to the pipes themselves. Clearing blockages may require professional plumbing assistance.

- Regular maintenance by a professional plumber can help prevent these problems or catch them early on. It’s important to address any issues promptly to avoid further damage and ensure the grinder pump system continues to function properly.

How to troubleshoot common issues with a grinder pump system?

If you encounter common issues with your grinder pump system, there are some troubleshooting steps you can take before contacting a professional plumber. Here’s what you can do:

- Check for Power: Ensure that the grinder pump is receiving power. Check the circuit breaker or fuse associated with the pump’s electrical supply. If there is a power outage, wait for the power to be restored and see if the pump resumes operation.

- Inspect Float Switch: If the pump is not turning on or off properly, check the float switch. Ensure that it moves freely and is not stuck. Gently lift the float to see if it activates the pump. If the float switch is damaged or not functioning, it may need to be adjusted or replaced.

- Clear Blockages: If you notice slow drainage or backups, there may be a blockage in the pipes. Avoid using chemical drain cleaners as they can damage the pump. Instead, try using a plunger or plumbing snake to clear any clogs. If the blockage persists, it’s best to call a professional plumber for assistance.

- Check Alarm System: If the alarm system is activated, it may indicate an issue with the grinder pump. Check the alarm panel for any error codes or indications of the problem. Consult the pump’s manual for guidance on troubleshooting specific alarm activations. If you cannot resolve the issue, contact a professional plumber.

- Avoid DIY Repairs: Grinder pump systems are complex, and attempting to repair or disassemble the pump yourself can do more harm than good. It’s best to leave major repairs or component replacements to qualified plumbing professionals.

- Remember, if you are uncertain or unable to troubleshoot the problem on your own, it is recommended to contact a professional plumber. They have the expertise and knowledge to diagnose and resolve issues with your grinder pump system safely and effectively.

How long does a grinder pump last?

The lifespan of a grinder pump can vary depending on several factors, including the quality of the pump, its usage, maintenance, and local conditions. On average, a well-maintained grinder pump can last between 10 to 15 years or more.

Regular maintenance plays a crucial role in extending the life of a grinder pump. Professional plumbers typically recommend scheduling regular inspections and servicing every 1 to 2 years. During these maintenance visits, the plumber can check the pump for any signs of wear, clean components, test operation, and address any issues that may arise.

Proper usage is also important. Avoid flushing or disposing of items that could damage the pump, such as grease, wipes, feminine hygiene products, or excessive toilet paper.

Additionally, local conditions can impact the lifespan of a grinder pump. Factors such as the quality of water, the presence of debris, excessive sediment, or corrosive materials can affect the pump’s longevity.

If you notice any unusual noises, decreased performance, or persistent issues with your grinder pump, it’s best to have a professional plumber inspect it to assess its condition and determine if any repairs or replacements are needed.

By following recommended maintenance practices and ensuring adequate usage, you can maximize the lifespan of your grinder pump and avoid premature failures.

What is the cost of a Residential grinder pump system?

The cost of a grinder pump system can vary depending on several factors such as the specific brand and model of the pump, the installation requirements, and any additional components needed for the system.

On average, the cost of a grinder pump system can range from $2,000 to $5,000 or more. This cost typically includes the grinder pump unit, control panel, installation materials, and labor. However, it’s important to note that this is a general estimate, and actual costs may vary based on your specific circumstances and location.

Additional factors that can influence the cost include the complexity of the installation, accessibility of the plumbing system, any necessary excavation or site preparation, and potential upgrades or modifications required to meet local plumbing codes.

To get an accurate cost estimate for a grinder pump system, it’s best to consult with a professional plumber who can assess your specific needs, evaluate the installation requirements, and provide you with a detailed quote.

Remember, investing in a quality grinder pump system and professional installation is crucial for reliable and efficient wastewater transportation in your home.

What is the average cost of grinder pump maintenance?

The cost of grinder pump maintenance can vary depending on several factors, including the specific tasks required, the complexity of the system, and the rates of the professional plumber or service provider. Typically, the average cost of grinder pump maintenance can range from $150 to $300 or more per visit.

During a maintenance visit, a professional plumber will inspect the grinder pump system, clean components, test the operation, and address any issues that may arise. They may also perform tasks such as checking the electrical connections, examining the float switch, inspecting the discharge and vent pipes, and ensuring proper functionality of the control panel.

It’s important to note that these cost estimates are general averages and can vary based on your location, the complexity of your system, and the specific maintenance requirements.

Remember, regular maintenance is crucial to keep your grinder pump system running efficiently and prevent costly repairs or replacements in the future. Investing in proper maintenance can save you money in the long run and prolong the lifespan of your grinder pump.

Sewage Cleanup Costs are Much Higher than than the Cost of Maintenance

The cost of sewage cleanup can vary significantly depending on the extent of the damage, the size of the affected area, and the specific cleanup requirements. Generally, professional sewage cleanup can range from $1,000 to $10,000 or more.

Several factors can influence the cost of sewage cleanup:

- Severity of the damage: The more extensive the damage, the higher the cost of cleanup. A small sewage backup may be less expensive to clean up compared to a major sewage overflow affecting multiple rooms or floors.

- Size of the affected area: The larger the area that requires cleanup, the more labor and resources will be necessary, potentially increasing the cost.

- Repair and restoration needs: If the sewage backup has caused damage to flooring, walls, furniture, or other belongings, the cost will include repairs and replacement of affected materials.

- Professional services: The cost of hiring a professional sewage cleanup company will depend on their rates, expertise, and the equipment required for the job.

It’s important to note that these cost estimates are general ranges, and the actual cost can vary based on your specific situation and location. It’s advisable to contact professional cleanup companies to assess the damage and provide you with a detailed quote.

Quick action is crucial when dealing with sewage cleanup to prevent further contamination and damage to your property. Contacting a professional sewage cleanup company promptly is essential for proper and safe cleanup, as well as minimizing costs in the long run.

What is the best way to maintain a Residential grinder pump system?

To maintain a residential grinder pump system and ensure its optimal performance, we have a full guide, titled Grinder Pump Maintenance Made Simple, which goes in full detail. For a quick rundown, follow these best practices:

- Follow Proper Usage: Only flush appropriate waste down the drain. Avoid disposing of items that can damage or clog the pump, such as grease, wipes, or feminine hygiene products. Use the garbage disposal properly, if applicable.

- Regular Maintenance: Schedule regular maintenance visits with a professional plumber. Generally, once every 1-2 years is recommended. During maintenance, the plumber will inspect the pump, clean components, test operation, and address any issues.

- Monitor Alarm System: If the grinder pump system has an alarm system, be attentive to any alarms or notifications. If the alarm goes off, it may indicate a problem that requires attention from a professional plumber.

- Protect from Debris: Keep the area around the grinder pump free from debris, leaves, and other objects that may obstruct or damage the pump. Do not place heavy objects on top of the pump or its access covers.

- Avoid DIY Repairs: Attempting to repair or disassemble the grinder pump yourself can lead to further damage. Leave major repairs or replacements to qualified plumbing professionals.

- Power Outages: During power out

- ages, the grinder pump may not function. Consider having a backup power source, such as a generator or battery backup, to ensure the pump continues operating during outages.

- Educate Household Members: Inform everyone in your household about the proper usage of the grinder pump system and the importance of following guidelines to avoid damage or clogs.

- Remember, regular maintenance is key to keeping your grinder pump system in good working condition. Consult with a professional plumber for specific maintenance recommendations based on your system’s requirements and local regulations. By following these practices, you can extend the lifespan of your grinder pump and prevent costly repairs or backups.

How to clean a grinder pump?

We have a full guide that covers this in detail, titled Grinder Pump Cleaning: Importance and Explanation, but cleaning a grinder pump typically involves the following steps:

- Turn off the power: Before starting any cleaning procedures, ensure the power to the grinder pump is turned off. This is essential for your safety.

- Access the pump: Find the access point for the pump, which is usually located in an underground basin or vault outside your home. Remove the cover or lid to access the pump.

- Remove debris: Carefully inspect the pump and remove any visible debris or objects that may have accumulated inside. Be cautious not to damage any components or disrupt the wiring.

- Clean the pump and impeller: Use a soft brush or cloth to clean the interior surfaces of the pump and the impeller. This will help remove any residual waste or buildup. Avoid using harsh chemicals or abrasive materials that may damage the pump.

- Check and clean the discharge and vent pipes: Examine the discharge and vent pipes connected to the pump. Ensure they are clear of any blockages or obstructions. If necessary, use a plumbing snake or similar tool to remove any clogs.

- Test the pump: After cleaning, securely close the access point and turn the power back on. Run a test cycle to ensure the pump is functioning properly and effectively pumping the wastewater.

- It’s important to note that while you can perform basic cleaning of the pump, more thorough or complex maintenance should be carried out by a professional plumber. Regular maintenance visits by a qualified plumber are recommended to ensure the grinder pump operates efficiently and to address any potential issues before they escalate.

- Always prioritize your safety when working with the grinder pump system and follow any specific instructions or guidelines provided by the manufacturer.

What are the signs of a failing grinder pump?

Several signs can indicate a failing grinder pump. If you notice any of the following signs, it’s important to address the issue promptly:

- Frequent backups or slow drainage: If you experience frequent backups in your plumbing fixtures, such as toilets, sinks, or showers, or if you notice slow drainage, it could indicate a problem with the grinder pump. The pump may be struggling to properly grind and pump the waste.

- Unusual noises: If the grinder pump starts making loud or unusual noises during operation, it could indicate issues such as worn-out components, damaged impellers, or loose parts. Squealing, grinding, or rattling sounds should not be ignored.

- Visual indicators: Inspect the area around the grinder pump for any signs of leaks or wet spots. Leakage can suggest a problem with seals or pipe connections, which may require immediate attention.

- Frequent cycling or pump malfunctions: Monitor how often the grinder pump cycles on and off. If it is cycling more frequently than usual or if it fails to turn on or off properly, it may indicate electrical or mechanical issues.

- Unpleasant odors: If you notice persistent foul odors emanating from the grinder pump or

- its vicinity, it could signal a possible issue with the pump operation or a clog in the system.

- Alarm system activation: Many residential grinder pump systems are equipped with alarm systems that notify you of potential problems. If the alarm goes off, it’s an indication that the system requires attention from a professional plumber.

- If you observe any of these signs, it’s crucial to contact a professional septic plumber experienced in grinder pump systems. If you are in or around the Chattanooga area, we would be happy to help you. We can assess the situation, diagnose the problem, and recommend the necessary repairs or maintenance to restore proper functionality. Prompt action can help prevent further damage, backups, or potential health hazards associated with a failing grinder pump.

How to prevent grinder pump blockages?

Preventing blockages in your grinder pump system is essential for its proper functioning and longevity. Here are some preventive measures you can take:

- Watch what goes down the drain: Avoid disposing of items that can clog the pump or pipes, such as grease, oil, wipes, feminine hygiene products, diapers, or excessive amounts of toilet paper. Dispose of these items properly in the trash.

- Use a sink strainer: Install sink strainers in your kitchen and bathroom sinks to catch large food particles, hair, or other debris before they enter the drain. Empty the strainer regularly to prevent buildup.

- Proper use of the garbage disposal: If you have a garbage disposal, use it in moderation and avoid overloading it with large amounts of food waste. Scrape excess food into the trash before washing dishes to minimize the amount of waste entering the disposal.

- Flush with water: After using the garbage disposal or flushing the toilet, run water for a few seconds to ensure proper flushing of the waste through the pipes and to prevent buildup.

- Regular septic tank maintenance: If your grinder pump system is connected to a septic tank, make sure to have the septic tank pumped and inspected regularly by a

- licensed professional. This helps prevent solids and debris from clogging the system and reaching the grinder pump.

- Educate household members: Teach everyone in your household about the proper usage of plumbing fixtures and the importance of not flushing or disposing of items that can clog the grinder pump system.

- Regular maintenance: Schedule regular maintenance visits with a professional plumber to inspect and service the grinder pump system. Maintenance includes inspecting and cleaning components, testing operation, and addressing any potential issues before they worsen.

By following these preventive measures, you can significantly reduce the risk of blockages in your grinder pump system. Remember, proper usage, regular maintenance, and being mindful of what goes down the drain are key to keeping your system running smoothly and avoiding costly repairs or backups.

What is the difference between a grinder pump and a septic system?

A grinder pump and a septic system are two different components of a wastewater management system.

A grinder pump is a specific type of pump used to move wastewater from a building to a sewer or septic system. It grinds solid waste into smaller particles and pumps them through pipes, typically when the plumbing in the building is located lower than the sewer or septic tank, or when the distance is too long for gravity to transport the waste effectively.

On the other hand, a septic system is a complete wastewater treatment system that is installed underground on a property. It consists of a septic tank and a drainfield (also known as a leachfield). The septic tank receives and stores wastewater from the building, allowing the solid waste to settle at the bottom and the liquid waste to flow out into the drainfield, where it is further treated and filtered through the soil.

Basically, a grinder pump is a specific pump used to move wastewater from a building, while a septic system is a complete wastewater treatment system that includes a tank and drainfield. The grinder pump helps to transport waste to a sewer or septic system, while the septic system treats and filters the wastewater before returning it to the environment.

What is the average power consumption of a grinder pump?

The average power consumption of a grinder pump can vary depending on factors such as the pump’s motor size, the specific model, and the frequency of use. On average, a grinder pump consumes around 700 to 1500 watts of electricity when operating.

It’s important to note that the power consumption of a grinder pump primarily relates to its operation during pump cycles when it is actively grinding and pumping wastewater. The pump’s motor is designed to run intermittently, meaning it turns on and off as needed to handle the wastewater flow.

Keep in mind that your grinder pump may not run continuously throughout the day. Its operation is typically triggered by the level of wastewater in the holding tank. The pump will activate when a certain level is reached, grind the waste, and pump it out, before turning off until the next cycle.

To get a more accurate assessment of the power consumption of your specific grinder pump, it’s best to consult the manufacturer’s specifications or contact a professional plumber who can provide you with more precise information based on the model installed in your home.

Remember, including the grinder pump’s power consumption in your electricity usage calculations can help you manage your energy consumption and plan accordingly.

How to reduce the power consumption of a grinder pump?

Reducing the power consumption of a grinder pump can help lower your energy costs. Here are some steps you can take:

- Water conservation: Minimize water usage to reduce the frequency of grinder pump cycles. Be conscious of water usage, avoid leaving faucets running unnecessarily, fix any leaks promptly, and use water-efficient appliances.

- Proper waste disposal: Be mindful of what goes down the drain to minimize solid waste in the grinder pump system. Avoid flushing items that can cause clogs or increase the load on the pump, such as grease, oil, wipes, or excessive toilet paper.

- Regular maintenance: Schedule regular maintenance visits with a professional plumber to ensure the pump is in good working condition. Regular maintenance helps optimize pump performance, ensuring it operates efficiently and avoids unnecessary energy consumption.

- Consider a control panel: Some grinder pump systems have control panels that allow you to adjust pump settings or schedule pump cycles based on your specific needs. Consult a professional plumber to explore if adding a control panel could help you better manage and reduce power consumption.

- Backup power consideration: If you experience frequent power outages, it may be worth considering a backup power source, such as a generator or battery backup, to ensure the grinder pump continues operating during outages. This can help prevent backups and reduce the need for the pump to run longer or more frequently once power is restored.

- Implement energy-saving practices: Explore other energy-saving practices in your home that can indirectly reduce power consumption, such as using energy-efficient lighting, appliances, and insulation.

- It’s important to note that while these steps can help optimize power consumption, the grinder pump’s power usage is primarily dictated by the wastewater flow and the pump’s operation. Consulting a professional plumber or referring to the manufacturer’s specifications can provide more tailored guidance specific to your grinder pump model and system.

- By incorporating these practices, you can help lower power consumption, reduce associated costs, and promote more efficient operation of your grinder pump system.

How to reduce the noise level of a grinder pump?

Grinder pumps can generate noise during their operation, but there are measures you can take to reduce the noise level. Here are some steps you can follow:

- Insulate the pump enclosure: If your grinder pump is housed in an enclosure, consider adding insulation or sound-absorbing materials to the enclosure. This can help dampen the noise produced by the pump.

- Install vibration isolating mounts: Mount the pump on vibration isolating mounts to minimize vibrations transmitted to nearby surfaces. This can help reduce the noise created by the pump’s operation.

- Position the pump away from living areas: If possible, locate the grinder pump in an area that is not directly adjacent to living spaces or areas that are frequently occupied. Increasing the distance between the pump and living areas can help reduce the perceived noise level.

- Modify plumbing fixtures: Check the plumbing fixtures connected to the grinder pump for any loose or faulty parts that may contribute to noise generation. Repair or replace any components that are causing excessive noise.

- Soundproof the surrounding area: Consider soundproofing the room or space where the grinder pump is located. Use acoustic panels, rugs, curtains, or other sound-absorbing materials to minimize noise reflection and reverberation.

- Regular maintenance: Regular maintenance by a professional plumber ensures the pump is working optimally and can help identify any issues that may be contributing to excessive noise. Addressing these issues can help reduce noise levels.

- Seek professional assistance: If noise remains a concern, consult with a professional plumber experienced in grinder pump systems. They can inspect the system, identify potential sources of noise, and provide recommendations for further noise reduction.

It’s important to note that some degree of operational noise is normal for grinder pumps. However, by taking these steps, you can minimize the noise level and create a more comfortable living environment.

What is the best way to dispose of grinder pump waste?

The best way to dispose of grinder pump waste is to follow local regulations and guidelines for wastewater management. Here are some general guidelines to consider:

- Sewer Connection: In many cases, grinder pump waste is connected to the local sewer system. This means that wastewater and ground-up solids from the grinder pump flow into the sewer network and are eventually treated at a wastewater treatment plant. It’s important to ensure that your grinder pump system is properly connected to the sewer in compliance with local plumbing codes.

- Septic Tank Disposal: If your property is served by a septic system rather than a public sewer, the grinder pump waste may flow into the septic tank. In this case, the waste is treated and periodically pumped out by a professional septic tank service provider according to the recommended schedule.

- Avoid Improper Disposal: It’s crucial to avoid improper disposal practices, such as dumping grinder pump waste directly into rivers, lakes, storm drains, or any location not designated for wastewater treatment. Improper disposal can lead to environmental pollution and harm aquatic ecosystems.

- Follow Local Regulations: Make sure to comply with local regulations regarding the disposal of grinder pump waste. These regulations may vary depending on your location, so it’s essential to check with your local health department or wastewater authority for specific guidelines.

- Professional Plumber Guidance: Consult with a professional plumber experienced in grinder pump systems for guidance on proper waste disposal practices in your area. They can provide specific recommendations based on your local regulations and help ensure you are following the correct procedures.

Remember, proper disposal of grinder pump waste is important for environmental protection and public health. Compliance with local regulations and guidance from professionals will help ensure that wastewater is managed responsibly and treated appropriately.

Special considerations of disposing waste in Chattanooga and the Hamilton County Area

When it comes to disposing of waste in Chattanooga, the Hamilton County, TN area, and areas of North Georgia like Ringgold, Rossville, and Fort Oglethorp, there are some special considerations to keep in mind:

- Sanitary Sewer System: Hamilton County has a comprehensive sanitary sewer system that handles the disposal and treatment of wastewater. If your property is connected to the sewer system, the grinder pump waste should flow into the sewer through the appropriate connections. It’s important to ensure your resdential grinder pump system is properly installed and maintained according to local guidelines.

- Septic Systems: In areas where a public sewer is not available, some properties in Hamilton County and North Georgia may rely on septic systems for wastewater treatment. If your property has a septic system, it’s crucial to follow the proper maintenance and pumping schedule recommended by the Hamilton County Health Department or a licensed septic service provider.

- Local Regulations: Hamilton County has specific regulations governing wastewater management and disposal. It’s essential to familiarize yourself with these regulations and ensure your grinder pump system or septic system is in compliance. The Hamilton County Health Department can provide guidance on local regulations and requirements.

- Household Hazardous Waste: When disposing of other waste materials, such as household chemicals, paints, oils, or batteries, it’s important to handle them separately from grinder pump waste. Hamilton County offers resources and designated drop off locations for proper disposal of household hazardous waste. For Septic Tank Pumping near Chattanooga and North Georgia, we are happy to help you.

- Proper Maintenance: Regular maintenance and inspection of your grinder pump system by a professional plumber are vital to ensure proper functioning and waste disposal. Follow the recommended maintenance schedule and guidelines provided by the manufacturer and local authorities.

- It’s crucial to stay informed about local regulations and guidelines for waste disposal in Hamilton County. Consulting with the Hamilton County Health Department or a professional plumber experienced in local regulations can provide specific advice tailored to your property and grinder pump system.

What are the environmental impacts of a Residential grinder pump system?

Grinder pump systems, like any wastewater management system, can have environmental impacts. Here are some important considerations:

- Energy Consumption: Grinder pumps require electricity to operate. The energy consumed by the pump contributes to greenhouse gas emissions, which can contribute to climate change. However, the overall energy impact of a grinder pump system is relatively small compared to other energy-consuming aspects of a household.

- Solid Waste Generation: Grinder pumps grind solid waste into smaller particles for easier transportation. While this helps prevent clogs and backups, it also introduces additional waste into the sewer or septic system. Proper grinding and disposal of solid waste are important to ensure efficient treatment and prevent any adverse environmental effects.

- Wastewater Treatment: The wastewater from grinder pump systems is typically treated at a wastewater treatment plant or through septic system processes. Proper treatment is crucial to remove pollutants and harmful substances before returning the water to the environment. Compliance with local regulations and regular maintenance of the grinder pump system help minimize potential environmental impacts.

- Resource Usage: The manufacturing, installation, and maintenance of grinder pump systems require the use of materials and resources. Proper design, installation, and maintenance practices help ensure resource efficiency and minimize waste generation.

- Mitigating Environmental Impacts: To reduce the environmental impacts of a grinder pump system, it is important to follow best practices such as proper waste disposal, regular maintenance, water conservation, and adherence to local regulations. Implementing energy-saving measures in your household, such as using energy-efficient appliances and reducing water consumption, can also indirectly contribute to reducing the environmental footprint of the system.

It’s worth noting that the environmental impacts of a grinder pump system are relatively small compared to the broader impacts of wastewater treatment and management.

Proper design, installation, and maintenance practices, along with responsible water usage and waste disposal, are key to minimizing any potential negative effects on the environment and ensuring the sustainable operation of the system.

[…] If you have more questions, check out our full Q&A Article about Residential Grinder Pump Systems […]