Introduction

Grinder pump systems are essential for efficient waste management in homes and businesses that are not connected to a central sewer system. These systems play a crucial role in breaking down waste and pumping it into septic tanks or central sewer systems. To ensure the longevity and optimal performance of these systems, understanding the importance of grinder pump maintenance is paramount.

This comprehensive guide aims to simplify grinder pump maintenance for homeowners, providing valuable insights and actionable tips. By following the maintenance guidelines outlined in this article, homeowners can prevent major issues, ensure the smooth operation of their grinder pump systems, and save on potentially costly repairs.

Now that we’ve established the significance of grinder pump systems and the purpose of this article, let’s delve into the essential maintenance practices that every homeowner should know.

II. Understanding Grinder Pump Systems

A. How does a grinder pump system work?

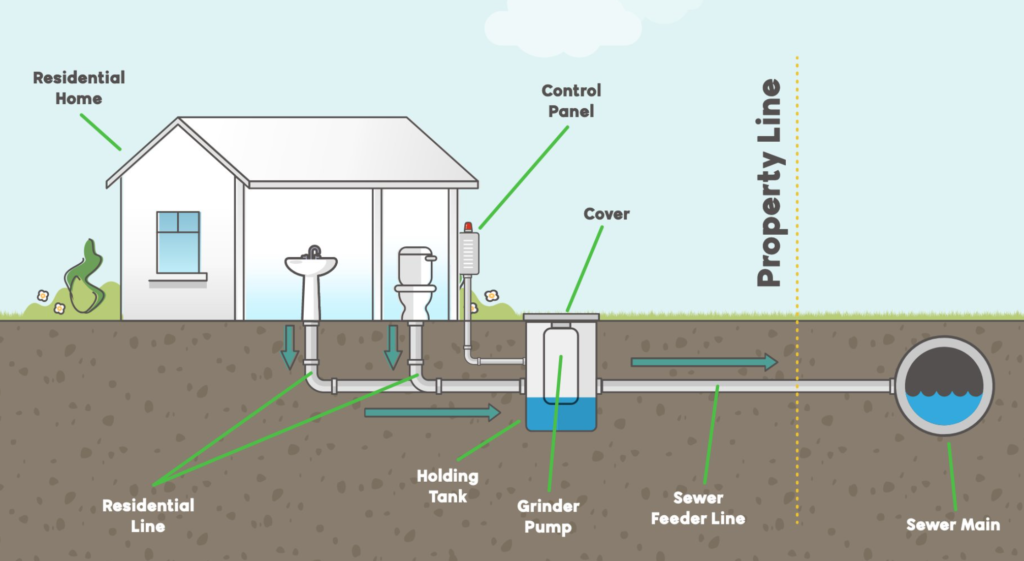

A grinder pump system operates by collecting waste from sinks, toilets, bathtubs, and washing machines in a holding tank. When the waste reaches a certain level, the pump activates and grinds up the waste into smaller particles. The pump then pumps the ground-up waste into a septic tank or central sewer system.

B. Key components of a grinder pump system

A typical grinder pump system consists of three main components: a holding tank, a pump, and a control box. The holding tank collects the waste, while the pump grinds and pumps the waste. The control box contains the alarm system, which alerts homeowners when the pump activates or if there’s a system failure.

C. Differentiating grinder pump systems from central sewer systems

Grinder pump systems are specifically designed for properties that are not connected to a central sewer system. Unlike central sewer systems, which collect and transport waste through a network of pipes, grinder pumps break down waste on-site and pump it into septic tanks or central sewer systems. Understanding this distinction helps homeowners recognize the specific maintenance requirements for their grinder pump systems.

Grinder pump maintenance is essential to ensure the efficient functioning of the system and prevent potential issues. In the following sections, we’ll explore how to identify when your grinder pump needs maintenance, ways to care for your system, common issues to watch out for, and the importance of contacting a professional service specialist for inspections and repairs.

III. The Importance of Regular Grinder Pump Maintenance

A. Extending the lifespan of your grinder pump system

Regular maintenance plays a crucial role in extending the lifespan of your grinder pump system. By following recommended maintenance schedules, you can ensure that the components of your system remain in good condition and continue to function efficiently. This helps avoid premature wear and potential breakdowns, ultimately saving you from costly repairs or replacements.

B. Preventing major issues and expensive repairs

Proactive maintenance is key to preventing major issues with your grinder pump system. Routine inspections can identify small problems before they escalate into significant failures. By addressing these issues early on, you can avoid potential sewage backups, environmental contamination, or even damage to your septic tank or sewer system. It’s essential to prioritize regular maintenance to mitigate the risk of costly repairs down the line.

C. Enhancing the efficiency of your grinder pump

Regular maintenance not only ensures the smooth operation of your grinder pump system but also enhances its overall efficiency. By keeping the blades sharp and the motor in optimal condition, your grinder pump can effectively break down waste and pump it away without strain. This helps maintain proper flow rates and prevents unnecessary energy consumption, contributing to lower utility bills and a more sustainable operation.

To make the most of your grinder pump system and reap these benefits, it’s crucial to stay proactive in your maintenance efforts. In the following sections, we’ll guide you through the signs indicating the need for maintenance, essential care practices, common issues to watch out for, and why it’s important to rely on authorized service specialists for inspections and repairs.

IV. Signs that Your Grinder Pump Needs Maintenance

A. Increased frequency of pump activation

If you notice your grinder pump kicking on more frequently than usual, it could be a sign that maintenance is needed. Excessive activation may indicate potential issues with the pump or an increase in waste accumulation. It’s important to address this promptly to prevent further complications.

B. Unusual noises emanating from the grinder pump

Unusual noises, such as grinding or clunking sounds, coming from your grinder pump can indicate problems with the motor or worn-out components. Ignoring these noises may lead to more severe damage and potential pump failure. Calling a qualified service specialist for inspection is recommended.

C. Detecting water leakage from the system

Water leakage around your grinder pump system is a red flag that should not be overlooked. Leaks can occur due to worn-out seals or gaskets, compromising the integrity of the system. Swift action is necessary to prevent water damage and potential environmental contamination.

D. Complete failure of the grinder pump

If your grinder pump stops functioning entirely, it’s crucial to address the issue promptly. A complete pump failure can lead to sewage backups and pose health and safety risks. Calling a professional service specialist immediately is the best course of action.

E. Observing reduced efficiency in the system

A decrease in the overall efficiency of your grinder pump system can indicate the need for maintenance. Factors like dull blades, worn-out bearings, or motor problems can diminish performance. Timely maintenance can restore the system’s efficiency and prevent costly breakdowns.

F. Consulting a qualified service specialist promptly

When you encounter any of these signs or suspect issues with your grinder pump system, it’s essential to consult a qualified service specialist promptly. They have the expertise to diagnose problems accurately and perform the necessary repairs or maintenance tasks. Taking proactive measures will prevent further damage and ensure the optimal performance of your grinder pump system.

In the following section, we will share preventive maintenance tips that can help you keep your grinder pump system in excellent condition and avoid potential issues.

V. Preventive Maintenance Tips for Grinder Pump Systems

To ensure the longevity and efficient operation of your grinder pump system, it’s crucial to follow these preventive maintenance tips:

A. Following manufacturer’s instructions and schedules

Read and adhere to the manufacturer’s instructions for your specific grinder pump model. They provide valuable guidance on maintenance tasks and recommended schedules. By following these instructions, you can stay on top of necessary maintenance and avoid potential issues.

B. Regularly inspecting the grinder pump for wear or damage

Perform periodic inspections of your grinder pump system to check for any signs of wear, damage, or leaks. Look for visual cues such as cracks, corrosion, or loose connections. Timely identification of problems can prevent further complications.

C. Maintaining a clear area around the grinder pump

Keep the area surrounding your grinder pump clear of debris, vegetation, and any obstructions. This ensures proper ventilation and easy access for maintenance or repairs. Additionally, a clutter-free environment minimizes the risk of accidents or damage to the pump.

D. Relying on professional servicing and repairs

While regular inspections and maintenance tasks are essential, it’s equally important to engage the expertise of a qualified service specialist for professional servicing and repairs. They have the knowledge and experience to identify underlying issues and provide appropriate solutions.

E. Installing a grinder pump protection device

Consider installing a grinder pump protection device as an extra layer of defense against potential clogs and system malfunctions. These devices intercept and capture items that can harm the pump, such as wipes, feminine hygiene products, paper towels, and grease. They help maintain the system’s optimal performance.

F. Avoiding items that can clog the system

To prevent clogs and maintain the smooth operation of your grinder pump system, avoid disposing of items down drains or toilets that can cause blockages. These include feminine hygiene products, diapers, paper towels, wipes, hair, grease, and food scraps. Proper disposal reduces the risk of pump failure.

While these preventive maintenance tips are valuable, remember that professional assistance is crucial for the overall health and reliability of your grinder pump system. If you encounter any problems or suspect issues beyond your expertise, it’s best to contact a qualified service specialist promptly.

In the next section, we will guide you through the step-by-step process of conducting grinder pump maintenance to ensure optimal performance and prevent potential complications.

VI. Conducting Grinder Pump Maintenance

Maintaining your grinder pump system is a crucial step in ensuring its optimal performance and longevity. Here’s a step-by-step process for conducting preventive maintenance:

A. Step-by-step process for preventive maintenance

- Begin by turning off the power supply to the grinder pump system. This ensures your safety during maintenance procedures.

- Inspect the grinder pump blades for any signs of wear, damage, or debris buildup. Clean the blades carefully to ensure their efficient operation.

- Test the alarm system to ensure it functions properly. The alarm is a vital safety feature that alerts you to potential system failures.

- Check the pump’s seals, gaskets, and connections for any signs of leaks or deterioration. Address any issues promptly to prevent further damage.

- Lubricate the necessary parts of the grinder pump according to the manufacturer’s recommendations. This helps maintain smooth operation.

- Clean the pump chamber and remove any accumulated solids or debris. This prevents clogs and enhances the pump’s efficiency.

B. Inspecting and cleaning the grinder pump blades

Regularly inspecting and cleaning the grinder pump blades is essential for optimal performance. Dull or damaged blades can compromise the system’s efficiency and lead to breakdowns. If you notice any wear or damage, it’s best to contact an authorized service specialist for professional assistance.

C. Testing and ensuring proper functioning of the alarm system

The grinder pump’s alarm system serves as a critical safety measure. It alerts you to potential failures or malfunctions in the system. Regularly test the alarm system to ensure it functions properly. If you encounter any issues or the alarm sounds frequently, reach out to a qualified service specialist for inspection and necessary repairs.

D. Routine maintenance tasks performed by authorized specialists

While some maintenance tasks can be handled by homeowners, certain routine maintenance procedures require the expertise of authorized service specialists. These professionals have the knowledge and tools to conduct comprehensive inspections, perform necessary repairs, and provide valuable guidance on maintaining your grinder pump system.

Remember, proper maintenance is key to keeping your grinder pump system running smoothly and avoiding costly repairs. If you’re uncertain or encounter complex issues during maintenance, don’t hesitate to contact a professional service specialist for assistance.

In the next section, we’ll discuss how to handle power outages and protect your grinder pump system from potential complications.

VII. Handling Power Outages and Protecting Your Grinder Pump System

Power outages can pose challenges to the functionality of your grinder pump system. It’s essential to understand the impact of power outages and take appropriate measures to protect your system. Here’s what you need to know:

A. Understanding the impact of power outages on grinder pump systems

During a power outage, your grinder pump will not function, which can lead to sewage backup in your home or business. This backup poses health and safety concerns for you and your family. It’s crucial to be aware of this potential issue and take necessary precautions.

B. Importance of having an alternative power source

To prevent sewage backup during power outages, it’s vital to have an alternative power source for your grinder pump system. Consider investing in a backup generator or a battery-powered backup system. These solutions ensure continuous operation and prevent sewage from flowing back into your property.

C. Water usage guidelines during power outages

When facing a power outage, it’s important to limit water usage until power is restored. Excessive water usage without proper grinder pump functionality can overload the system and lead to further complications. By conserving water during this time, you can minimize potential issues.

D. Clearing pipes and preventing sewage backup after power restoration

Once power is restored, it’s essential to take proactive steps to clear any blockages and prevent sewage backup. Run water in all sinks, toilets, and drains to help flush out any accumulated debris or stagnant water. This process ensures the smooth flow of sewage through the system and prevents any potential backups.

While these guidelines can assist you in handling power outages, it’s recommended to contact a professional service specialist for assistance. They possess the expertise to address specific challenges and provide tailored solutions to protect your grinder pump system effectively.

Next, we’ll delve into the step-by-step process of conducting grinder pump maintenance to ensure optimal performance and longevity.

VIII. Common Grinder Pump Issues and Troubleshooting

Grinder pump systems, like any mechanical equipment, can experience common issues over time. Here’s what you need to know about troubleshooting these problems:

A. Addressing the problem of dull blades and reduced efficiency

Over time, the blades in your grinder pump can become dull, leading to reduced efficiency. This can result in improper grinding of waste and strain on the pump. If you notice decreased performance, it’s crucial to have the blades inspected and sharpened or replaced by a professional.

B. Dealing with worn-out bearings and the need for replacements

Worn-out bearings in your grinder pump can cause strange noises and eventually lead to pump failure. If you hear unusual sounds coming from the pump, it’s essential to have the bearings checked and replaced if necessary. This ensures smooth operation and prevents further damage.

C. Tackling water leaks caused by deteriorated seals or gaskets

Leaks in your grinder pump system can occur when the seals or gaskets wear out over time. These leaks can lead to water damage and potential environmental contamination. If you notice any signs of leaks, such as pooling water or moisture, it’s important to contact a professional service specialist to address the issue promptly.

D. Troubleshooting motor problems and potential failures

The motor in your grinder pump is critical for its operation. If the motor fails, the pump will stop working altogether. If you experience a complete pump failure or the pump is not functioning as expected, it’s essential to call a professional service specialist to diagnose and resolve the motor-related problems.

While some minor issues may be resolved by homeowners, it’s best to consult a professional for troubleshooting and repairs. They have the expertise to identify the root causes of these issues and provide effective solutions, ensuring the longevity and optimal performance of your grinder pump system.

Next, we’ll explore the consequences of grinder pump failure and the importance of taking timely action to avoid potential risks.

IX. The Consequences of Grinder Pump Failure

Grinder pump failure can have serious consequences for homeowners and businesses. It’s crucial to understand the potential risks and take appropriate action to prevent them:

A. Health and safety risks associated with backups

When a grinder pump fails, sewage can back up into your home or business, leading to significant health and safety concerns. Exposure to raw sewage can pose a risk of bacterial and viral infections, respiratory issues, and other health complications. Promptly addressing grinder pump issues is essential to protect yourself and your family. Sewage cleanup can be a difficult and involved process, so you can also seek a septic specialist to help you with it.

B. Environmental impact and contamination concerns

A failing grinder pump can cause sewage to leak into the environment, leading to groundwater contamination and environmental damage. Sewage contains harmful substances that can pollute natural water sources and harm ecosystems. By promptly addressing grinder pump failures, you help prevent these environmental risks.

C. Costly repairs and the risk of septic tank or sewer system collapse

If grinder pump issues are left unattended, they can escalate and lead to more extensive damage. This can result in costly repairs and potential collapse of your septic tank or sewer system. Timely intervention by a professional service specialist is vital to mitigate the risk of further damage and minimize repair costs.

It’s important to recognize the gravity of grinder pump failure and take immediate action when you suspect any issues. Contacting a professional service specialist is the best course of action to assess and address the situation, ensuring the well-being of your home, the environment, and your finances.

Next, we’ll explore preventive maintenance tips for grinder pump systems, empowering homeowners with actionable steps to keep their systems in optimal condition.

VIII. Common Grinder Pump Issues and Troubleshooting

A. Addressing the problem of dull blades and reduced efficiency

Over time, the blades in your grinder pump can become dull, leading to reduced efficiency and potential system breakdowns. It’s crucial to address this issue promptly to avoid further complications. Consider the following steps:

- Professional Inspection: Contact an authorized service specialist to inspect your grinder pump system. They will assess the condition of the blades and determine if they need sharpening or replacement.

- Blade Maintenance: If your grinder pump blades are dull, the specialist can sharpen or replace them as necessary. This will restore the pump’s efficiency and prevent overloading, reducing the risk of breakdowns.

- Preventive Measures: To prevent future issues, adhere to a regular maintenance schedule recommended by the manufacturer. Following these guidelines will help keep your grinder pump operating at its best and extend its lifespan.

Other things to consider:

- Dull blades can hinder the grinder pump’s ability to effectively break down waste, leading to reduced efficiency.

- To resolve this issue, it’s best to call a professional service specialist who can inspect and replace the dull blades promptly.

- Regular maintenance by a qualified expert will ensure your grinder pump operates at its optimal capacity.

B. Dealing with worn-out bearings and the need for replacements:

- Over time, the bearings in your grinder pump can wear out, resulting in unusual noises and potential pump failure.

- When you notice these signs, contacting an authorized service specialist is crucial to prevent further damage.

- They have the expertise to diagnose the issue, replace worn-out bearings, and restore your grinder pump’s smooth operation.

C. Tackling water leaks caused by deteriorated seals or gaskets:

- Leaks in your grinder pump system can occur due to worn-out seals or gaskets, compromising the system’s integrity.

- If you detect water leaks, it’s essential to act swiftly to prevent water damage and potential environmental contamination.

- Contacting a professional service specialist is recommended to address the issue promptly and ensure proper repairs or replacements.

D. Troubleshooting motor problems and potential failures:

- The motor in your grinder pump may encounter issues over time, leading to pump malfunction or complete failure.

- If you experience problems with the motor, it’s crucial to seek professional assistance to diagnose and resolve the issue.

- A qualified service specialist can troubleshoot motor problems and determine the best course of action for repair or replacement.

Remember, seeking the help of a professional service specialist is the most effective way to address common grinder pump issues and ensure the longevity and reliable performance of your system.

IX. The Consequences of Grinder Pump Failure

Grinder pump failure can have serious consequences for homeowners and businesses. It’s crucial to understand the potential risks and take appropriate action to prevent them:

A. Health and safety risks associated with backups

When a grinder pump fails, sewage can back up into your home or business, leading to significant health and safety concerns. Exposure to raw sewage can pose a risk of bacterial and viral infections, respiratory issues, and other health complications. Promptly addressing grinder pump issues is essential to protect yourself and your family.

B. Environmental impact and contamination concerns

A failing grinder pump can cause sewage to leak into the environment, leading to groundwater contamination and environmental damage. Sewage contains harmful substances that can pollute natural water sources and harm ecosystems. By promptly addressing grinder pump failures, you help prevent these environmental risks.

C. Costly repairs and the risk of septic tank or sewer system collapse

If grinder pump issues are left unattended, they can escalate and lead to more extensive damage. This can result in costly repairs and potential collapse of your septic tank or sewer system. Timely intervention by a professional service specialist is vital to mitigate the risk of further damage and minimize repair costs.

It’s important to recognize the gravity of grinder pump failure and take immediate action when you suspect any issues. Contacting a professional service specialist is the best course of action to assess and address the situation, ensuring the well-being of your home, the environment, and your finances.

Next, we’ll explore preventive maintenance tips for grinder pump systems, empowering homeowners with actionable steps to keep their systems in optimal condition.

X. Maximizing the Lifespan of Your Grinder Pump System

A. Proactive Maintenance Strategies:

Implementing effective measures to prolong the lifespan of your grinder pump system is essential. Here are some tips to maximize its longevity:

- Regularly inspect the grinder pump and its components for signs of wear, leaks, or damage. Address any issues promptly by contacting a professional service specialist for assistance.

- Follow the manufacturer’s instructions and recommended maintenance schedules meticulously. Adhering to these guidelines ensures optimal performance and helps prevent potential breakdowns.

- Keep the grinder pump area free of debris and obstructions. This prevents potential damage and ensures smooth operation.

- Consider scheduling professional maintenance at regular intervals to ensure comprehensive servicing and the identification of any underlying issues.

B. Benefits of Professional Servicing by a septic plumber :

Engaging the expertise of a qualified grinder pump specialist offers numerous advantages:

- Experienced professionals possess in-depth knowledge of various grinder pump systems, enabling them to diagnose and address issues accurately.

- They have access to specialized tools and equipment, allowing them to perform maintenance tasks effectively and efficiently.

- Professionals can provide valuable guidance on best practices for care and usage, maximizing the lifespan and efficiency of your grinder pump system.

- By entrusting your grinder pump maintenance to experts, you can have peace of mind, knowing that your system is in capable hands.

XI. Selecting a Reliable Grinder Pump Service Provider

A. Credentials and Experience:

When choosing a service provider for your grinder pump system, consider the following factors:

- Verify the service provider’s qualifications, certifications, and licenses. Ensure they have the necessary expertise and training to handle grinder pump maintenance and repairs.

- Look for professionals with extensive experience in the field. A reputable service provider with a proven track record is more likely to deliver high-quality service and customer satisfaction.

- Consider their knowledge of various grinder pump system brands and models. Having experience with a wide range of systems demonstrates their versatility and proficiency.

B. Prompt Response and Emergency Services:

Emergencies can happen unexpectedly, and a reliable service provider should be equipped to respond promptly. Look for professionals who offer quick response times, especially in urgent situations such as system malfunctions or alarms.

C. Comprehensive Service Offerings:

Opt for service providers that offer a comprehensive range of grinder pump services, including routine maintenance, inspections, repairs, and replacements. Having a one-stop solution ensures you can rely on them for all your grinder pump needs.

D. Positive Reviews and Recommendations:

Take the time to read customer reviews and seek recommendations from trusted sources. Feedback from others who have used the service provider’s expertise can provide valuable insights into their professionalism, reliability, and customer satisfaction.

E. Service Agreements and Warranties:

Inquire about service agreements and warranties offered by the service provider. These agreements can provide added protection and peace of mind, ensuring that you receive continued support and coverage for your grinder pump system.

Note: The sections above are outlined in markdown format to maintain consistency. Please let me know if you need any further adjustments or additional information.

If you’re looking for a Chattanooga Septic Specialist, you can call Chatta-Rooter Plumbing at (423) 509-9748

XII. Conclusion

A. importance of regular grinder pump maintenance :

- Regular grinder pump maintenance is vital for ensuring the longevity and efficient operation of your system.

- By following a maintenance schedule and promptly addressing issues, you can avoid costly repairs and potential system failures.

- It’s recommended to consult a professional service specialist to handle any maintenance or repair needs.

B. Recap of the key points :

- We explored how a grinder pump system works, the common issues it may face, and the significance of preventive maintenance.

- Dull blades, worn-out bearings, water leaks, and motor problems are some of the challenges homeowners may encounter.

- Following manufacturer’s instructions, conducting regular inspections, and seeking professional assistance are essential steps.

C. Encouraging homeowners to take proactive measures for a durable system:

- As a homeowner, being proactive about grinder pump maintenance can save you time, money, and headaches in the long run.

- Stay vigilant for signs of trouble, such as unusual noises, frequent alarms, or reduced efficiency.

- Contacting a professional service specialist promptly is the best course of action to address any issues and ensure your system runs smoothly.

Remember, by investing in regular grinder pump maintenance and seeking professional assistance when needed, you can enjoy a reliable and efficient system that serves your home for years to come.

If you have any questions or require professional grinder pump services, don’t hesitate to reach out to our authorized service specialists.

[…] fixtures, such as in basements or crawl spaces. However, like all mechanical devices, regular grinder pump maintenance is required in order to ensure they function […]

[…] By chattanoogasepticrepair@gmail.com Chatta-Rooter Plumbing July 5, […]